Returnable transport packaging: pooling to suit your needs

From baked goods and meats to pharmaceutical and automotive products: Interzero develops, implements and manages individual solutions for the pooling of returnable transport packaging. Our services can handle any category of merchandise and are especially suitable for fragile products or goods that are difficult to handle such as foodstuffs.

Optimising environmental performance and the supply chain

Our reusable plastic container (RPC) conserves energy and resources, saves on packaging material and avoids waste. Our pooling solutions also increase the efficiency of logistics flows, reduce per-unit and per-kilometre costs, and enable transparent tracking for every piece of RPC.

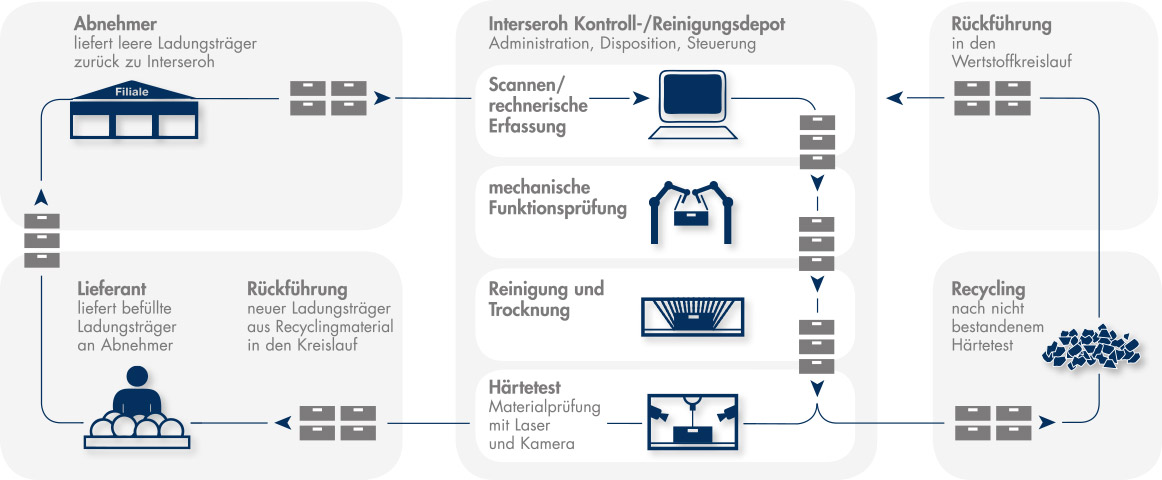

Record, inspect and clean

Interzero manages a life cycle that sets standards: in our inspection and cleaning depots, we record and identify each and every in- and outbound piece of RPC. We inspect, clean and dry all folding crates and containers according to high standards for hygiene and inspection. We use modern laser and camera technology to identify potential defects, repairing or recycling packaging as required.

Your benefits at a glance

Individual

We develop solutions tailored precisely to your needs – including transit packaging that is a perfect match for your type of merchandise and your supply chain.

Cost-effective

We scrutinise the typical cost drivers of administration, logistics and packaging to see where processes can be optimised to reduce costs.

High-performance

We manage, plan and operate pooling systems in real time. We maximise efficiency, e.g. by minimising the items of transit equipment in use at any one time.

Transparent

We ensure that all receptacles – i.e. folding crates and containers – can be tracked individually to enable the effective monitoring and optimisation of total stocks and stock on hand.

Service-oriented

We use our online portal to handle your order. Each posting is immediately visible: quickly, simply and around the clock.

Sustainable

We apply stringent environmental standards, using plastics made from innovative recycled materials to systematically close the resource loop.

Head of Customer Service | Interzero Deposit Solutions GmbH

Frequent questions of our customers

- Was bedeutet Pooling?

- Für wen eignen sich Pooling-Systeme?

- Kann der Status der Bestellung eingesehen werden?

- Wie schwer dürfen Mehrweg-Transportverpackungen beladen werden?

- Wo befinden sich die Interzero Waschdepots für die Mehrweg-Transportverpackungen?

- Wie viele Depots und Hubs werden von Interzero geführt?

- Wie viel kostet die Führung eines Behälters pro Umlauf?

- Ist ein Datenaustausch zwischen dem ERP-System des Kunden und der Mehrwegplattform von Interzero möglich?

- Wie funktioniert ein pfandfreies Pooling-System?

- What does “pooling” mean?

The term “pooling” in a logistics waste management context refers to the shared use of common resources – in this case, transport packaging. Interzero has set up a pooling system for returnable transport packaging (RTP) in the fruit and vegetable sector to close the logistics loop for this kind of transport packaging. Within this system, RTP crates are processed in a circular system with a focus on logistics management and supply chain optimisation.

- Who can benefit from pooling systems?

For recurring processes such as deliveries involving the same or similar goods from the same or similar suppliers, pooling offers an alternative to single-use transport packaging. The reuse of returnable transport packaging (for example) avoids packaging waste and conserves resources. RTP crates also benefit logistics processes by improving transportation safety and being easily stackable.

- Can I view the status of my order?

Yes. Since our platform can be used to view each individual asset and display its location (track/trace), full transparency for all stakeholders is assured for both status and stocks.

- What is the maximum load permitted for returnable transport packaging crates?

Returnable transit packaging crates currently may hold no more than 12 kg of goods, since OSH regulations mean personnel must be able to lift them safely.

- Where are the Interzero cleaning depots located for returnable transport packaging?

In Mönchengladbach and Sankt Leon-Rot, Germany.

- How many depots and hubs are operated by Interzero?

Interzero currently operates two inspection and cleaning depots for RTP crates in Germany: one in Mönchengladbach and one in Sankt Leon-Rot. At these depots, each crate is logged, damage is assessed and parts are replaced as necessary. The RTP crates are then cleaned, dried, sorted by size/height and shipped out again to customers.

- How much does it cost to operate one container per “loop”?

Since costs always depend on the particular pooling system in operation, they are affected by the total number of assets managed, the type of transport packaging used, the type of pooling system (open or closed) and the individual deposit system in place. The per-loop cost is always less than the cost of procuring new, single-use transport packaging out of PPC or wood of equal value.

- Can data be exchanged between a customer ERP system and the multi-use platform operated by Interzero?

To ensure our pooling system operates at maximum efficiency, rapid and transparent data exchange is required among our partners. Accordingly, there is always the option of connecting to an available ERP system in order to synchronise stocks and requirements.

- How does a zero-deposit pooling system work?

A zero-deposit system requires the meticulous tracking of its assets, since no deposit is paid when these are delivered to customers.